Circular solution for sludge recycling in Norwegian fish farming

Photo: Benjamin A. Ward (for Ragn-Sells)

Photo: Benjamin A. Ward (for Ragn-Sells)New circular technology from the Norwegian business network ARAL turns waste from salmon farms into commercial nutrients and biogas for green energy. Now Eide Fjordbruk has commissioned the world’s first full-scale system, allowing the company to expand production while lowering their environmental and climate impact.

– Circular systems for salmon farm waste means less pressure on the ocean, putting the waste to new use and enabling more production on existing sites. We are proud to help Eide Fjordbruk deploy the first of many systems, says Vidar Svenning Olsen, CEO of environmental company Ragn-Sells Norway.

Fish farming provides protein-rich food, but the biological waste from farms is rich in nutrients like phosphorus and nitrogen, and risk contributing to eutrophication. In Norway alone, 9,000 tonnes of phosphorus are released into the ocean every year. The new full-scale system developed by the business network ARAL prevents these nutrients from reaching the sea, turning them instead into valuable resources.

In order to protect the environment, the amount of nutrients a fish farm is allowed to emit is limited. The new system drastically reduces pressure on the surrounding sea, enabling sustainable farm companies such as Eide Fjordbruk to increase production without violating its permit.

– By collecting and circulating the waste, we can ramp up production while lowering emissions and energy consumption. This way, Norwegian fish industry can contribute to mitigating the food crisis of the world without the risk of exceeding planetary boundaries, says Sondre Eide, CEO of Eide Fjordbruk.

Photo: Benjamin A. Ward (for Ragn-Sells)

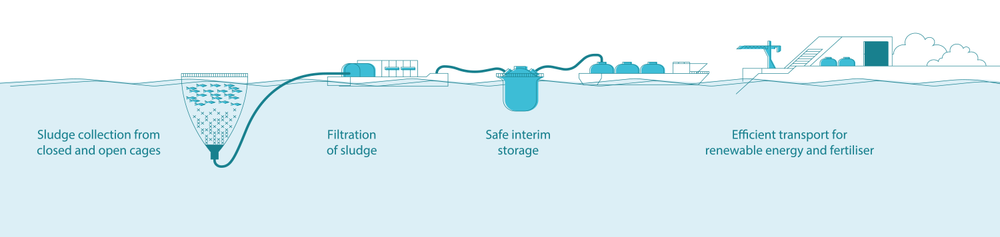

The system consists of several components, all from the business network ARAL. First, Framo LiftUP sludge collection ensures that sludge and dead fish are collected instead of sinking to the ocean floor. The filtered sludge goes to intermediate storage in a loading buoy from Aquapro before being taken care of by Ragn-Sells Havbruk logistics.

The sludge can be put to use in several ways. The nutrients are captured and circulated for use in fertiliser or feed, meaning that the system is truly circular as the feed goes back into fish farming. The remaining sludge is used in the production of biogas, providing renewable energy, and helping to offset the climate impact of food production. Ragn-Sells has established transports of waste from the Norwegian fish industry to biogas facilities in Denmark and will now add the sludge.

– The oceans can feed many people world-wide, but we have to harvest its riches in a sustainable and circular way. This system has the potential to substantially increase the production of fish in Norway as well as many other countries, without the risk of eutrophication which threatens coastal fish populations, says Pär Larshans, Director of Sustainability at Ragn-Sells Group.

The circular system will be fully operational at Eide Fjordbruk’s site in Hardangerfjorden during November 2022.

For further information, please contact

Pär Larshans, Director of Sustainability, +46709272963, par.larshans@ragnsells.com

Emma Ranerfors, Press Officer, +46107232416, press@ragnsells.com

About Ragn-Sells Group

The environmental company Ragn-Sells converts waste into raw materials that can be be used over and over again. Ragn-Sells drives the transition to a circular economy through solutions that reduce its own and other actors' environmental and climate impact. Ragn-Sells wants to be living proof that caring for the earth and business go hand in hand. Ragn-Sells is a family owned corporate group founded in 1881. The company operates in five countries and employs 2,500 persons. In 2021, Ragn-Sells’ turnover was SEK 7.6 billion. www.ragnsells.com